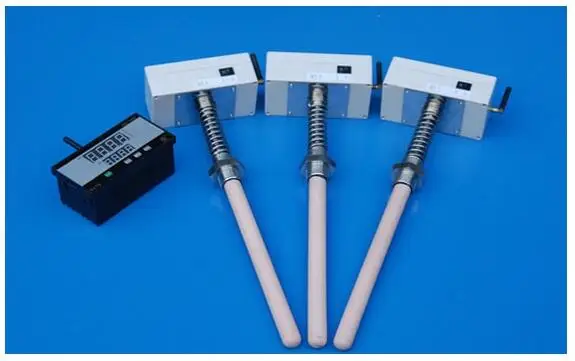

wireless temperature controller for Tunnel kiln rotary furnace and other Furnace

Product description:

Main technical indexes and feature

1.Reliable transmission line of distance up to 1500m; by using GFSK modulation; According to the thickness of the wall , material, the signal can pass through 2 to 5 walls.

2.Support 255 acquisition equipment wireless networking, computer acquisition software can be wireless data acquisition, viewing, export data;

3.The equipment support networking, through the mobile phone APP remote monitoring data (optional);

4.The device supports Modbus RTU communication protocol (we default is wireless data acquisition method, device also supports wired data acquisition, if need to be wired, please confirmed before buying);

5.The carrier frequency is 315-915 MHz, professional reading band, no need to apply frequency;

6.The optimization of man-machine interface, users can set up quickly;

7.User defined password lock function, it can prevent the misoperation of the user;

8.It can be used for point-to-point, point to multipoint communication, various combinations of;

9.The power supply: table DC +4.5V~+5.5V; AC 90~250V 50Hz the main table

Main technical indexes and feature

| accuracy | ±0.5%FS±1 |

| Relay electric shock control output | 220VAC 7A (Resistive load) |

| Alarm mode | The full range, relay output |

| supply voltage | Main Meter: 50Hz AC90-250V: sub Meter: DC4.5-5.5V (optional with exclusive custom high temperature lithium battery) |

| work environment | -40~70 (100 DEG C, time less than 1 minutes) (RH = 85%, no condensation), non corrosive and occasions without the interference of a strong magnetic field |

| Power consumption | ≤4w |

| insulation resistance | The power supply to the relay outputs 1500V/AC one minute; the power supply to the input, the relay to input 500V/AC one minute |

| Radio transmit power | Wireless power: 20dbm, the receiving current 25mA, the maximum emission current 85mA |

| Implementation standards | This product is the implementation of the Shanghai enterprise standard Q/SOFM1-2004 |

Installation process

Rectangular square hole of the mounting instrument according to the size of the opening of the surface of the disk

When the installation of multiple instruments, the distance between the left and right two holes should be greater than 25mm; the distance between the upper and lower two holes should be greater than 30mm.

The instrument is embedded in the surface of the disk.

Insert mounting bracket in instrument mounting groove

Push the mounting bracket, and the instrument panel and the panel are combined firmly, and tighten the screw.

Cleaned instrument after Power off.Please use a soft cloth or cotton paper clearly display, no hard objec Touching

Instrument installed in the following environment

Atmospheric pressure:86~106Kpa

Ambient temperature:0~50